This hands-on course focused on the full lifecycle of product creation—from concept to physical prototype. We explored a range of digital and physical fabrication tools including laser cutting, UV Printing, 3D printing, and advanced modeling softwares like Fusion 360 and Clo 3D. Emphasizing both technical precision and creative design, we also worked with materials innovation such as Bemis tape for seamless construction. The course emphasized iterative bag design, user-centered thinking, and the integration of cutting-edge technology into functional prototypes.

I designed and sewed a lined tote bag using heavyweight selvedge denim, with the pattern drafted in Adobe Illustrator. The project emphasized functional design, clean construction, and durable finishing using high-quality materials.

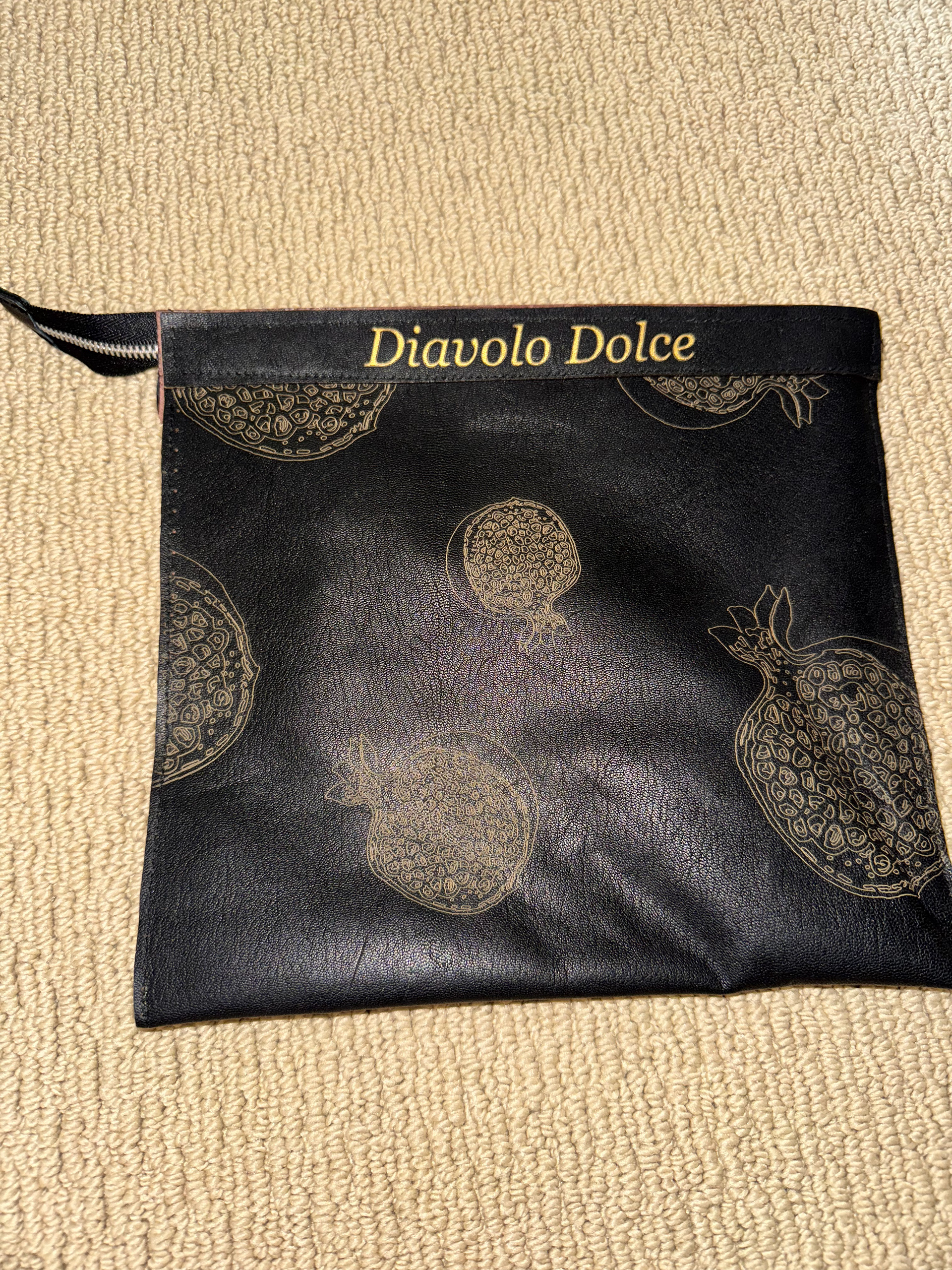

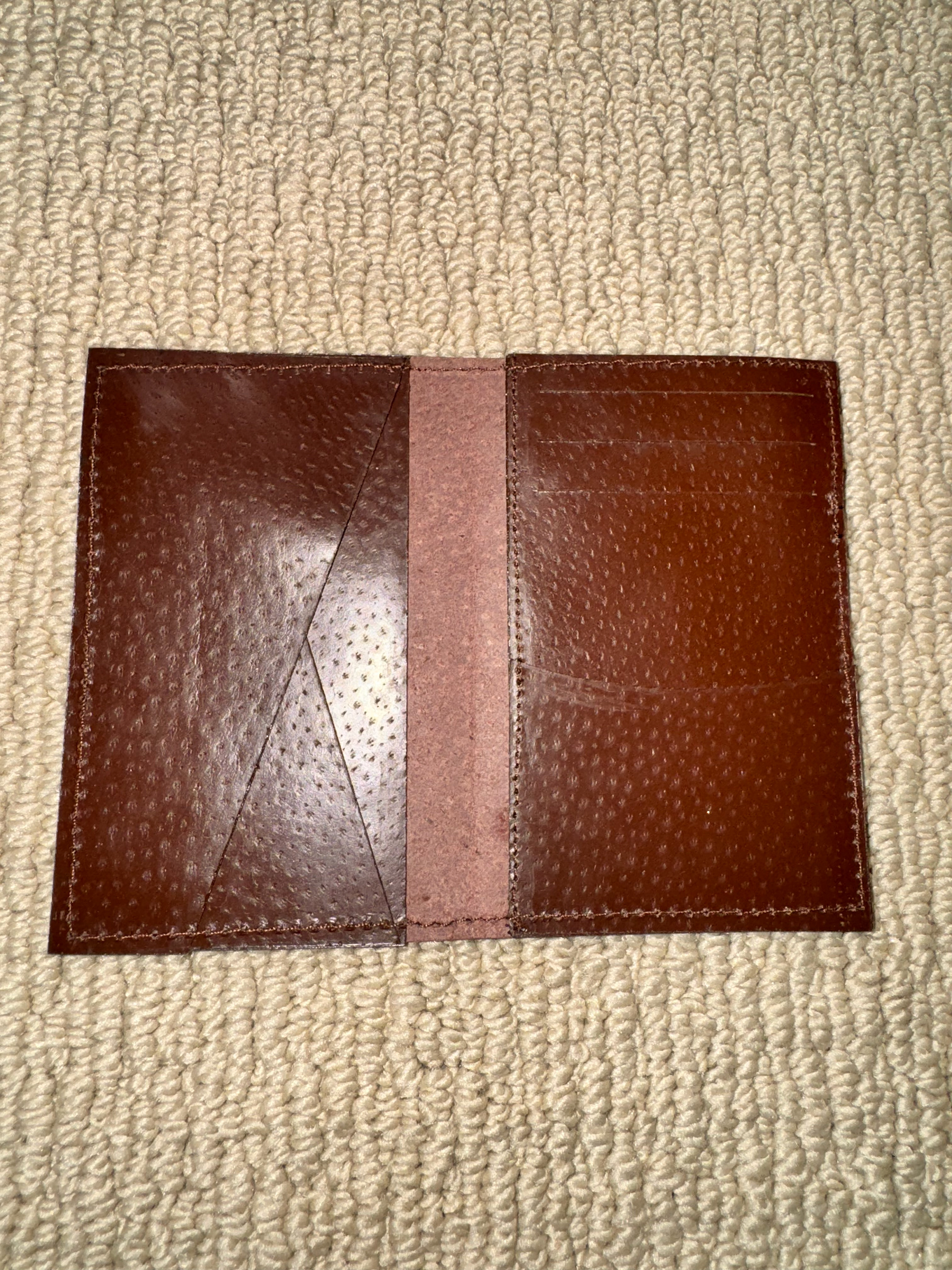

I designed and created a laser-cut leather wallet featuring a hand-drawn pomegranate motif, which was digitized in Adobe Illustrator and converted into vector art for laser etching. The piece was finished with hand-painted details and leather finishing techniques, highlighting the full process from sketch to software to fabrication.

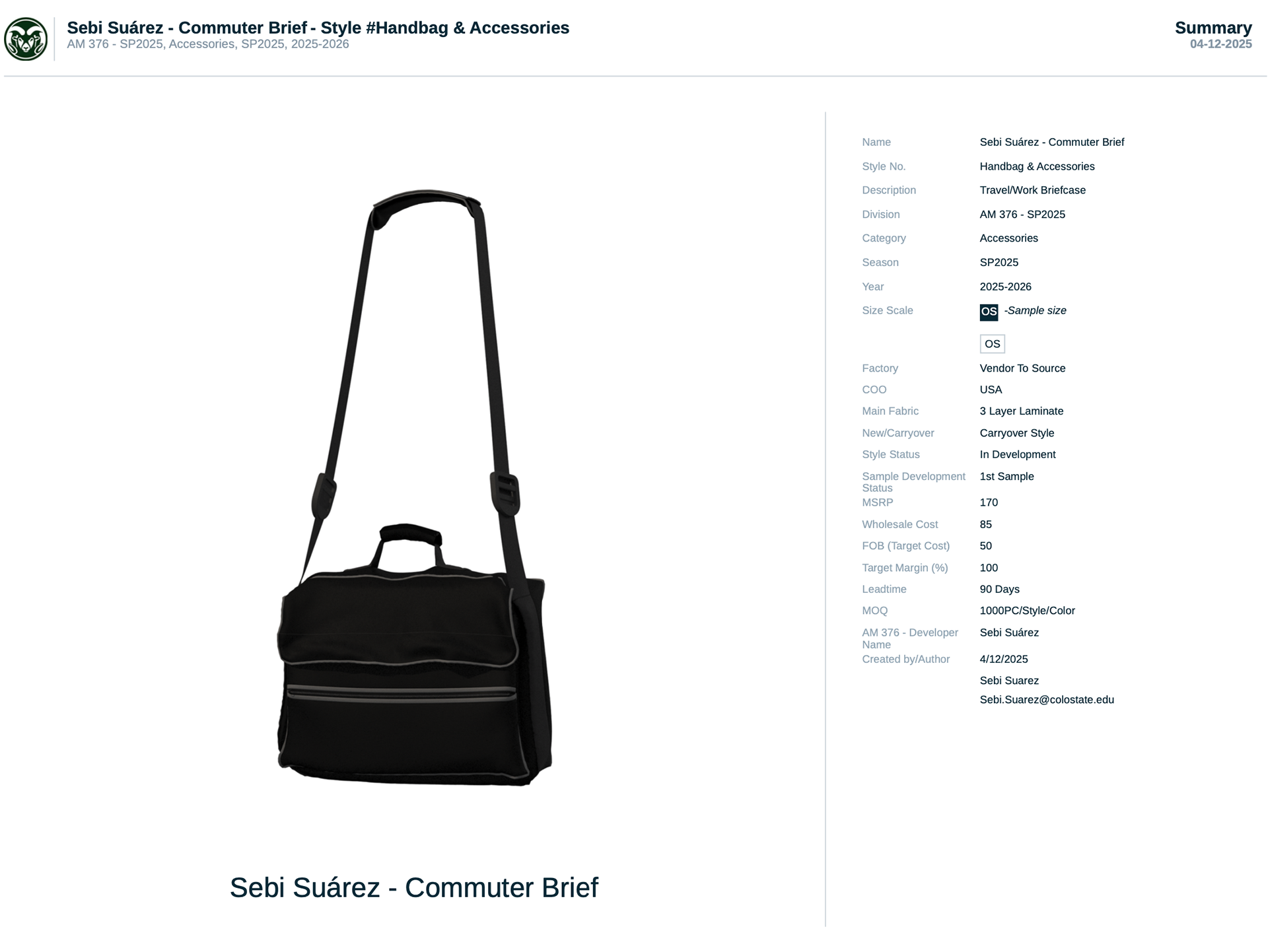

In this project, we focused on digitally recreating and customizing a Fjällräven-style bag in Clo 3D. I developed a fully rendered model, exploring construction details, material behavior, and hardware placement. The project also included creating multiple colorways to visualize design variations in a realistic 3D environment, showcasing the versatility of the bag and refining my skills in digital prototyping and presentation.

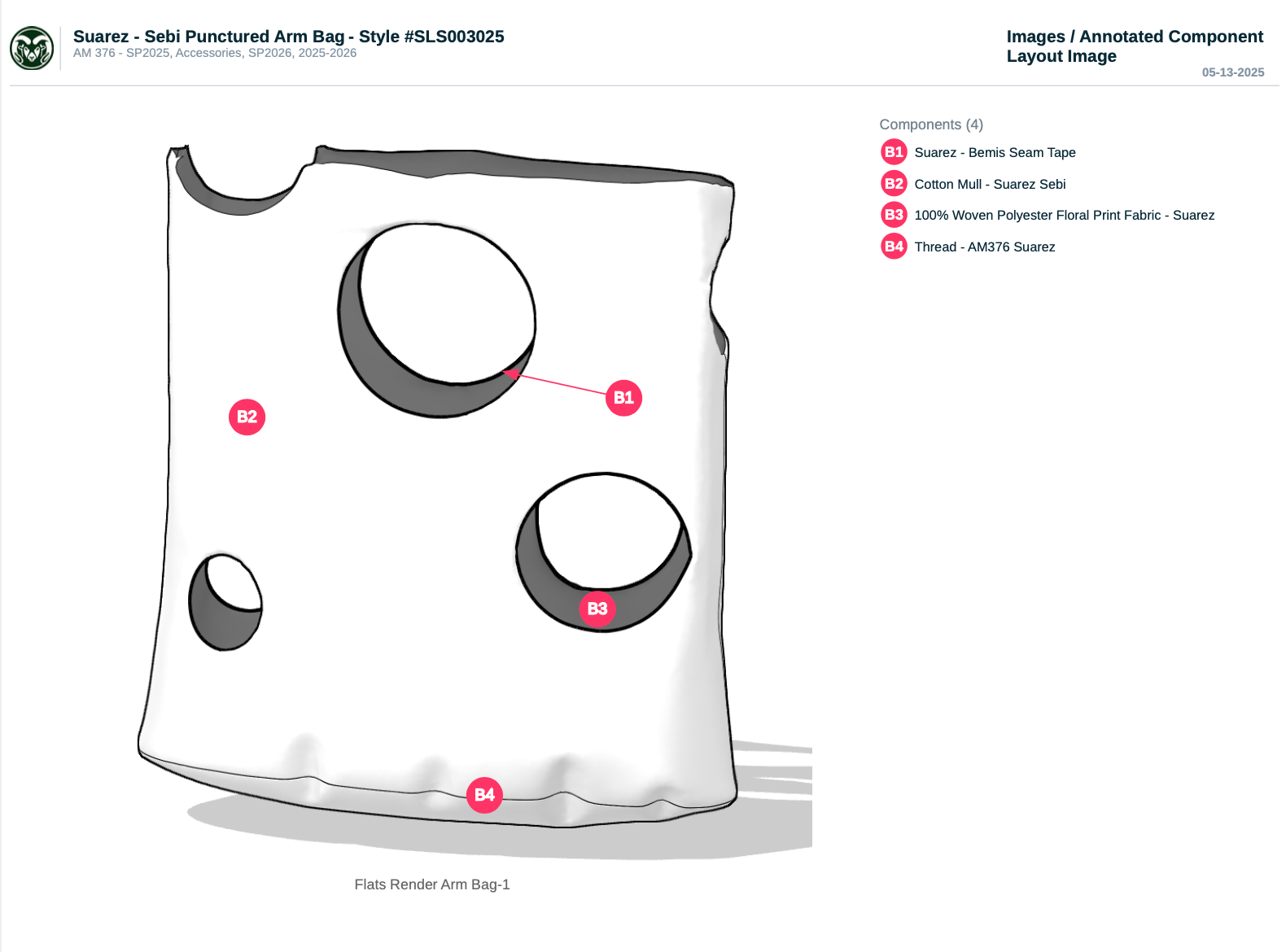

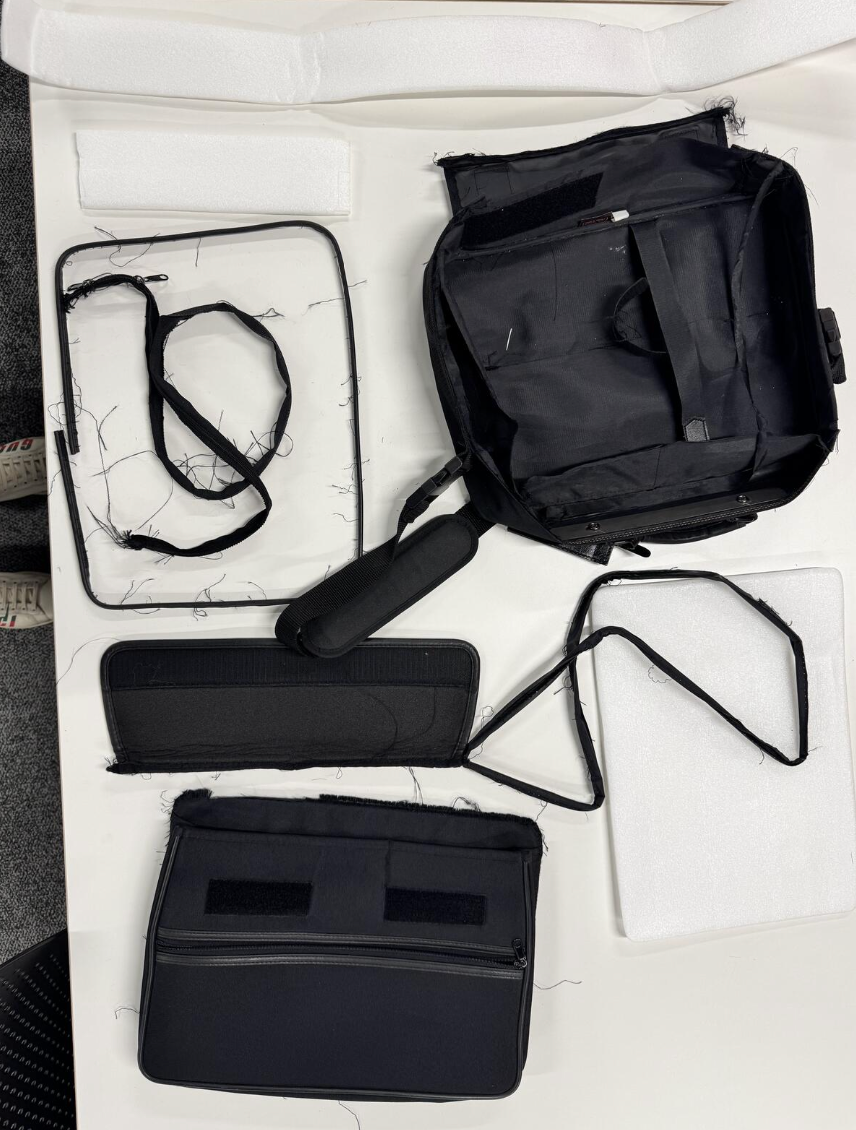

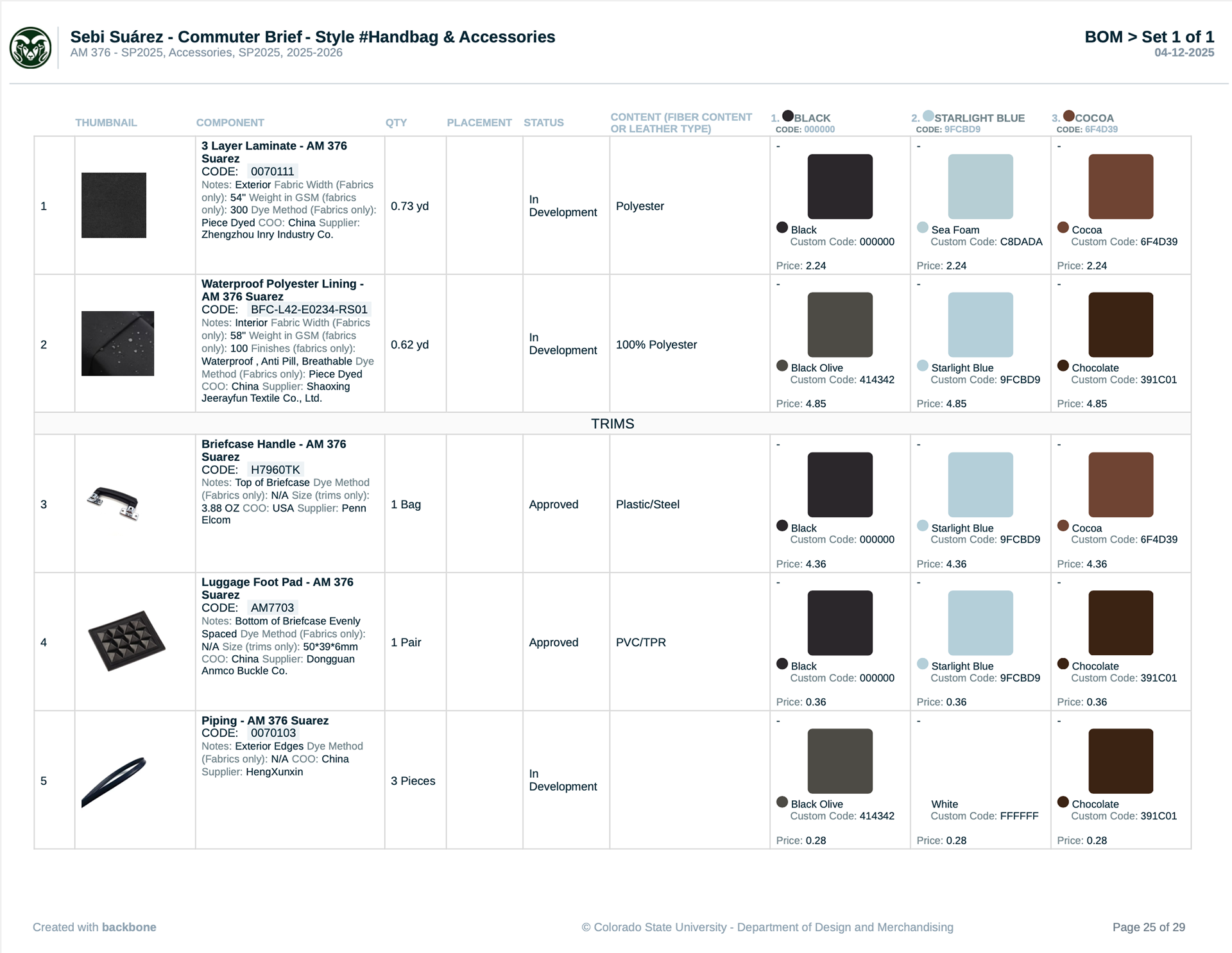

I reverse-engineered a manufactured bag by deconstructing it, then recreated the pattern digitally in Adobe Illustrator. The design was rendered and virtually sewn in Clo 3D to visualize construction and fit. I finalized the project in Backbone, where I assembled a complete, production-ready tech pack—including detailed specifications, a bill of materials, and construction notes.

For my final project, I designed and constructed a fully original bag that pushed the boundaries of my technical and creative skills. The process began with hand-drawn sketches, which were then translated into digital patterns and artwork. I hand-painted the surface design and transferred it using MX fiber reactive dye sublimation. The bag featured a custom 3D-printed chain created in Fusion 360, laser-cut and etched components, and edge finishing using Bemis tape for a seamless, modern look. From initial concept to prototyping and final execution, this project brought together traditional techniques and advanced technology to create a fully realized, production-ready piece.